In low margin businesses like food, beverage, and hospitality, operators cannot afford to miss out on profits. Even worse, they can't afford to watch those profits go down the drain. Literally.

Beer programs can be great profit centers in the food and beverage industry. They can serve as entertainment centers that serve up the perfect pints of beer. They affect the experience you provide and ultimately your bottom line. And whether you're opening a new bar or retrofitting an existing venue, every decision you make will help create beer-drinking events for your customers.

If your beer system is so important, then, what should you look for, and how much can your bar save just by using the right equipment? The right system should be:

ENGINEERED FOR EXCELLENCE

With Perlick beer systems, our exclusive vapor-sealed trunk housing design and beer line engineering protects beer temperature better than any other beer system on the market – consistently delivering a satisfying beer drinking experience for your patrons. Nothing beats copper coolant lines placed in direct contact with every beer line to ensure temperature integrity all the way to the tap, and it’s 17% more efficient than poly.

BALANCED FOR PERFORMANCE

Perlick Glycol Cooled Dispensing Towers and Faucets are factory balanced to optimize efficiency and assure solid beer flow for maximum profit potential. All dispensing heads are factory restricted to ensure a balanced system.

CUSTOMIZED FOR YOU

Our team of experts will partner with you to design a beer system that uniquely fits your situation – from the tower design, to the number and length of beer lines, to critical temperature delivery components, to the amount of pressure needed to push the beer to the tap. We design your system with your needs in mind to get the beer right – the first time.

So where's the savings?

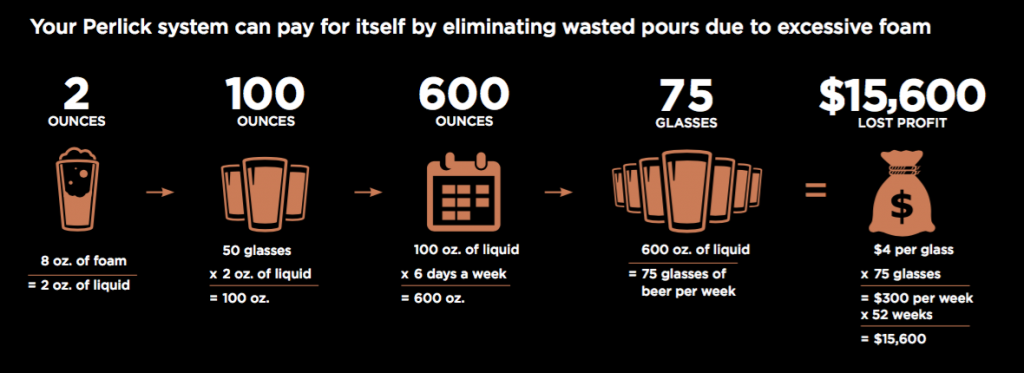

Simply put, all of these elements work together with other innovative Perlick features to deliver the perfect pour, every time. That means just the right amount of head - not too much, not too little. A flat beer means inferior flavor for customers and reduced keg yield for operators. Too much foam, and bars can waste up to $15,000 per year. Here's how:

(Click to Enlarge)

Thanks for your thoughts on beer systems. We agree, a lot goes into it, and that's why we love offering educational content on our blog! Thanks for Reading!